Calibration of mechanical measurands

Testo Industrial Services is characterised by an extensive mechanical laboratory, specialised in the calibration of pressure, torque, angle of rotation, force and acceleration measurement technology.

High-precision and modern measuring equipment ensure traceable and manufacturer-independent calibration of your mechanical test equipment. Both ISO/factory calibrations and calibrations recognised according to ISO/IEC 17025:2017 are possible.

In order to maintain quality and safety standards, it is of fundamental importance that you can rely on the results of the measuring equipment used. Here we are at your side.

Your advantage: Our competence

- Primary laboratory for the calibration of working and reference standards (acceleration and pressure)

- Established and standard-compliant laboratory processes

- Accreditation up to 500 m/s² (sine) and up to 0.5 kg test item mass in the acceleration range

Our innovations:

- Temperature based pressure calibration

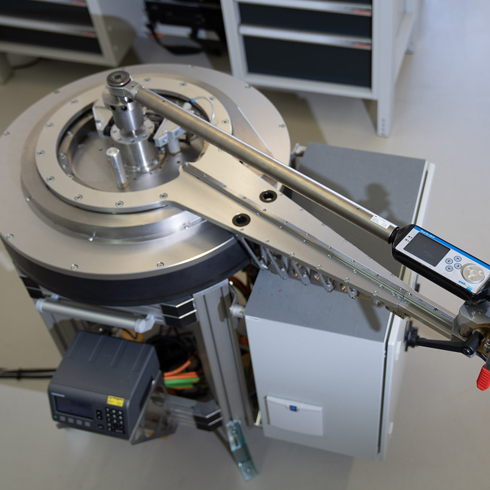

- Rotation angle test stand

- Accreditation up to 500 m/s² in the frequency range 3 Hz - 10 kHz

- Torque calibration between 0.01 Nm to 5 kNm

- Dynamic pressure calibration

- Description of TEDS (Transducer Electronic Data Sheet) devices

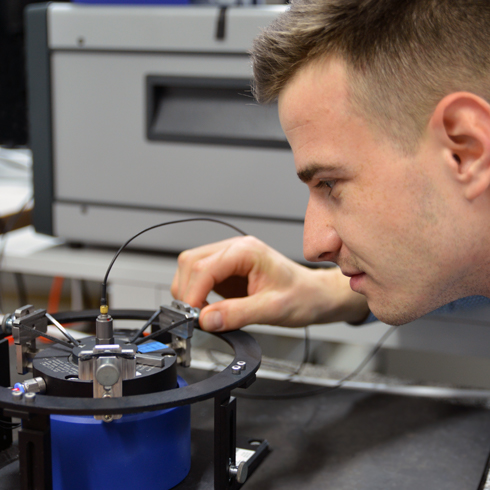

Insight into our mechanical calibration laboratory

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.Static pressure

The determination and monitoring of the prevailing pressure plays an outstanding role in many areas. In our in-house laboratories we can offer you accredited calibrations according to DIN EN ISO/IEC 17025/2018 up to a pressure of 1200 bar. Our laboratories are equipped with a wide range of primary, reference and working standards for this purpose. In addition, factory calibrations can be carried out with a pressure of up to 5000 bar. Our laboratory is based on two different types of reference: Pressure balances and pressure regulator. In addition, we have created the possibility of carrying out temperature-based pressure calibrations for up to 20 transmitters in our laboratory. Calibration is carried out in a temperature cabinet in a temperature range from -30 °C to 120 °C at -1 to 210 bar.

In the field of static pressure, for example, we are specialized in the following measuring devices

- Digital and analogue pressure test equipments: Additel 681; SIKA D2

- Pressure test equipments with digital display: Testo 511, Greisinger GMH1100

- Pressure transmitter with electrical output signal: Keller PA-33X; Kulite XTL-198

- Pressure regulator: WIKA CPC6050; GE DRUCK Pace5000

- Pressure calibrators: Fluke 719; Beamex MC6

Dynamic pressure

The sensitivity of pressure sensors deviate under dynamic input loads from purely static loads. In order to be able to guarantee real operating conditions in a dynamic application field also during calibration, dynamic pressure calibration is suitable. Our newly developed method enables true dynamic calibration of pressure sensors. The realization of traceable, dynamic pressure calibrations is unique since previous methods rely on static or slowly changing input signals.

Dynamic pressure calibrations are possible with our secondary calibrator in a measuring range between 20 bar and 300 bar. In parallel, the temperature can be controlled between 20 °C and 200 °C.

In the field of dynamic pressure , we specialize in piezoelectric, -resistive and -capacitive sensors:

- PCB Piezotronics 106B50, 106B51, 106B52, 112B05, 113B21, (...)

- Kistler 601CBA, 601CAA, 6052C, (...)

- AVL GP15DK, GU21D, GR15D (...)

Torque

Bolted connections with firmly defined forces are indispensable in many industrial sectors.

ISO and DAkkS-accredited calibrations for your torque wrenches, screwdrivers and torque testers can be carried out on our specially equipped calibration systems with a measuring range from 0.01 Nm to 3,000 Nm in accordance with standard specifications.

Due to increasing demands for higher torques, we are able to carry out DAkkS-accredited and ISO/factory calibrations for your torque sensors such as torque measuring shafts and torque measuring flanges in a measuring range from 0.2 Nm to 5,000 Nm. On-site calibrations are also possible from 0.4 Nm to 5 kNm.

- Torque wrenches/screwdrivers according to DIN EN ISO 6789 or DKD-R 3-7

- Torque testers according to DKD-R 10-8

- Torque sensors according to DIN 51309:2022

In the field of torque, for example, we are specialised in the following measuring devices:

- Torque wrench: Stahlwille 730; Hazet 5000er+6000er; Garant; Gedore Tohnichi; Proxxon; WIHA 7441 + 7443; Wera; Kanon

- Torque screwdriver: Atlas Copco& BCP; BCV

- Torque tester: Norbar; Stahlwille 7728; Stahlwille 7721; Stahlwille 7723; Hios; Mark 10

- Torque sensor: HBM T4WA; Schatz; Burster

Rotation angle

With the help of our rotation angle test stand we are ideally equipped for the calibration of your rotation angle sensors and measuring systems, as well as torque and rotation angle wrenches according to VDI/VDE 2648 part 1 and 2.

In our laboratory in Dachau we have the possibility to carry out the combined DAkkS calibration of your rotary encoders with a rotational speed of < 0.2 1/min and thus belong to the top performers in this field. In principle, any measuring points between 0° and 360° with a measurement uncertainty of 0.06° (direct) or 0.5° (indirect) are possible. Take a look at our accreditation certificate.

In the field of rotation angles, we specialise in the following measuring devices, for example:

- Torque sensors with angle option: HBM T4WA

- Torque wrench with protractor: GWK Quantec; SCS; Gedore E-Torc

- Rotary encoder: Wachendorf

Force and scales

A wide variety of force test equipment and force transducers must be calibrated at regular intervals. Testo Industrial Services features a force calibration device with a measuring range of up to 250 kN.

All common force test equipment and force transducers can be calibrated using our reference force calibration equipment, where the force is determined via the elastic deformation of a body. Calibration is performed by means of a comparative measurement; a high-precision reference standard ensures traceability.

You can also benefit from our expertise in the calibration of scales. We offer complete calibration for various types of scales, including precision scales, bench scales and platform scales up to 200 kg. For the highest requirements, we carry out DAkkS calibrations up to 80 kg directly on your premises. We also offer reliable calibration of hanging scales and spring scales up to 250 kN.

In the field of force and scales, for example, we are specialized in the following measuring devices:

- Force test equipments: Chatillon DFE II; Alluris FMI; Sauter FL

- Strain test equipment force transducer: HBM U2B; Burster 8524; ME-Measurement Systems KM

- Piezo force transducer: Kistler 9311B

- Load cells/Hydraulic pressure transducer:Tecsis F1115

- Precision and plattform scales

- Table scales

- Hanging and spring scales

Acceleration

In industry, vibration forces act during various work processes, which are measured with the help of acceleration sensors. Our calibration service of accelerometers and vibration meters covers a wide and complex range of applications in almost all branches of industry. Here we offer manufacturer-independent DAkkS-accredited and verifiable (traceable) acoustic calibrations. Vibrations that occur during calibration are easily absorbed by our 2.6 ton sandstone table.

With our expertise we are available for secondary sine calibrations of vibration calibrators, vibration transducers such as monoaxial and triaxial sensors, vibration meters (in the frequency range from 0.2 to 20,000 Hz) up to special individual solutions for contactless vibration frequency counters or vibro-pads. Calibration is performed according to the principle of secondary comparison calibration in accordance with DKD-R 3-1 ISO 16063-21 (vibration calibration).

We offer you a full DAkkS calibration of almost all vibration test equipment, take a look at our accreditation certificate. In addition to calibration, we also offer the possibility to repair your recording devices in our service center in Hamburg as well as to adjust your devices according to manufacturer specifications in our laboratories.

In the field of acceleration, for example, we are specialized in the following measuring devices:

- Vibration transducers from any manufacturer: Althen, Brüel&Kjaer, CTC; Dytran, Endevco, Honeywell, ifm

- Vibration calibrators: Brüel&Kjaer, Metra Measurement and Frequency Technology, PCB Piezotronics, MTS

- Vibration meters: Brüel&Kjaer Vibro, db Prüftechnik, Fluke, Nti Audio, SKF

Success stories

We support you in your projects and are committed to your goals. Here you will find an excerpt from the references of our successful projects:

Know-how

Our know-how summarized for you: In our Knowledge Centre you will find helpful know-how from our experts on mechanical calibration or dive into an interesting technical article.

Our scope of services for you

Our scope of services includes standard ISO calibrations as well as accredited DAkkS calibrations. Here you will find an excerpt of the services we offer in our laboratories and at your site.

| Measured variable Print: Digital and analog pressure test equipments, pressure test equipments with digital display, pressure transmitters with electrical output signal, pressure regulators, pressure calibrators | Calibration DAkkS-Accredited* | On-site calibration |

|---|---|---|

| Negative and positive overpressure between -1 bar and 1200 bar | ||

| Absolute pressure between 0.03 bar and 1201 bar | ||

| Primary calibration for pressure controllers from -1 bar to 70 bar (relative pressure) and from 0.03 bar to 70 bar (absolute pressure) | ||

| Temperature-based pressure calibration in the range -30°C to 120°C at -1 bar to 210 bar (relative pressure) and 0.03 bar to 210 bar (absolute pressure) |

| Measured variable Torque and angle of rotation: Torque wrenches, analysis wrenches, electric and pneumatic torque wrenches, torque sensors / transducers, angle of rotation sensors | Calibration DAkkS-Accredited* | On-site calibration |

|---|---|---|

| Indicating and triggering torque wrenches (left/right) from 1 to 1000 Nm | ||

| Torque screwing tools incl. angle option | ||

| Electric and pneumatic torque wrenches from 0.1 to 5 Nm | ||

| Torque testers / calibrators and torque sensors from 1 to 1000 Nm | ||

| Angle of rotation transducer/encoder at 12 points between 0 and 360° | ||

| Torque screwdriver from 1 cNm | ||

| Torque transfer key class 1 | ||

| Indicating and triggering torque wrenches (left/right) up to 3000 Nm |

| Measured variable Force: Load cells, load cells, force testers, spring balances, contactor, precision balances | Calibration DAkkS-Accredited* | On-site calibration |

|---|---|---|

| Tensile and compressive loads between 10 N and 250 kN | ||

| Precision scales and balances up to a maximum load of 80 kg | ||

| Scales up to a maximum load of 200 kg | ||

| Single weights up to 500 kg | ||

| Weight sets according to OIML R111 up to 10 kg |

| Measured variable Acceleration: Vibration transducers, vibration meters, Vibration calibrators | Calibration DAkkS-Accredited* | On-site calibration |

|---|---|---|

| Vibration transducers monoaxial or triaxial and determination of the transmission coefficient | ||

| Vibration calibrators at the operating points (fixed values) | ||

| Vibration measuring devices monoaxial or triaxial and determination of the sensor transmission coefficient | ||

| Calibration of the amplitude frequency response at approx. 5 -10 fixed frequencies (sine). Frequency calibration range from 0.2 Hz to 20 kHz with amplitudes up to 500 m/s² |

| Further | Calibration DAkkS-Accredited* | On-site calibration |

|---|---|---|

| Crimping pliers | ||

| Hardness testers Shore | ||

| Pipettes |

*In the lab

To read

Take a look at our topic-specific brochures and learn more about the calibration of your thermodynamic measuring instruments: