Maximizing Production Shutdowns at VALEO VISION SYSTEMS

Downtime comes at a cost—lost time, lost money, and reduced efficiency. Every hour a machine sits idle can lead to economic setbacks and potential delays. To help our customer, VALEO VISION SYSTEMS, we found a solution to minimize these risks.

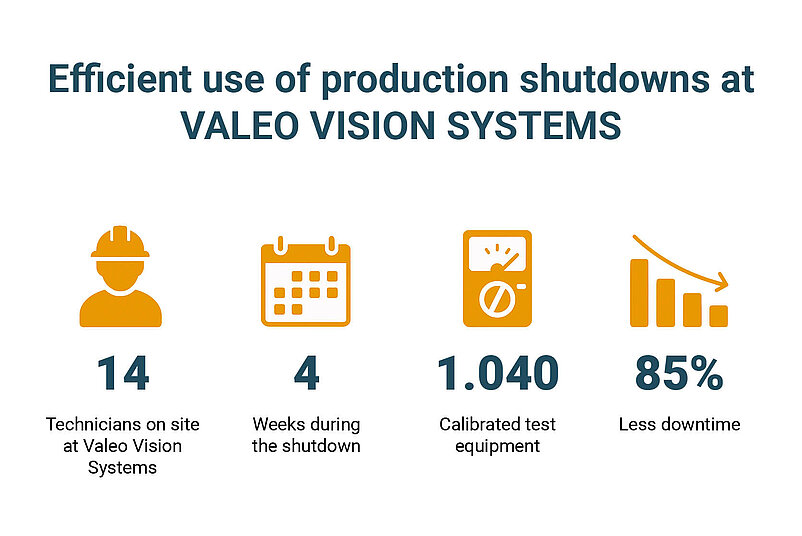

By strategically utilizing scheduled shutdown periods, we executed a thorough on-site calibration - without any additional disruption to production. Thanks to our mobile calibration service, VALEO VISION SYSTEMS not only upheld its consistently high quality standards but also achieved notable savings in both time and costs.

VALEO VISION SYSTEMS: A Pioneer in Driver Assistance Technology

VALEO VISION SYSTEMS, a key division of the Valeo Group, stands at the forefront of camera systems and driver assistance technologies worldwide. With a dedicated team of approximately 850 professionals based in Tuam, Galway (Ireland), the company continues to push the boundaries of innovation in automotive safety.

Quality assurance is upheld through an extensive test equipment pool, housing over 1,000 precision measuring devices. This sophisticated technology—comprising electrical, thermodynamic, and mechanical test instruments—ensures that stringent standards for driver assistance systems are consistently met.

To maintain peak performance, VALEO VISION SYSTEMS requires a flexible and dependable calibration partner — one that adheres to international standards, maximizes efficiency, and completes the entire calibration process during scheduled downtime, ensuring uninterrupted operations.

Tailored On-Site Calibration: The Ideal Solution

Through close collaboration with our customer and extensive Europe-wide flexibility, we crafted a highly efficient, customized approach:

- Accredited calibration services—covering electrical, thermodynamic, and mechanical measurements to ensure peak accuracy

- Flexible on-site calibration—conducted seamlessly during short-term scheduled shutdowns

- Uncompromising quality standards—supported by an extensive reference measuring equipment pool and a network of internationally available calibration experts

- Clear and transparent communication—keeping the customer informed at every stage, from challenges to solutions

This streamlined approach guarantees precision, efficiency, and reliability—delivering calibration exactly when and where it’s needed.

The result: higher quality, no additional costs due to downtime and satisfied customers

Through strategic planning and efficient implementation, we were able to ensure that:

- Over 95% of calibrations are carried out on site within the planned time frame

- The remaining measuring devices were also calibrated on time by sending them to one of our calibration laboratories across Europe

- All test equipment continues to meet the highest precision and conformity to standards

- Process reliability and quality have been significantly improved

- Customer satisfaction and long-term cooperation have been strengthened

Regular calibration and maintenance are essential for meeting both regulatory requirements and your own stringent quality standards. Our tailored service ensures that you can proactively mitigate risks with precision and efficiency.

Testo Industrial Services stands as your trusted full-service provider, offering expert support through a vast Europe-wide network of technicians. With mobile reference measuring instruments, we deliver calibration directly on-site—seamlessly aligned with your scheduled plant shutdowns for maximum convenience and minimal disruption.

Your contact person