Calibration of dimensional measurands

In our dimensional calibration laboratory we calibrate your length measuring equipment with the highest precision. These include indicating test euqipments, measuring standards, test euqipments and angles.

In order to ensure the measurement results, our premises are air-conditioned to a temperature of 20 °C ± 1 K. This ensures standard-compliant and reliable calibration in our dimensional laboratories. For the calibration of test equipment blocks, even rooms with a temperature range of 20 °C ± 0.5 K are available.

Characterized by a high number of calibrations per day, many processes are optimized and automated in order to relieve the time-consuming manual calibration process.

Our laboratory has a fully automated measuring robot, which calibrates calipers for you within a very short time, with very low measurement uncertainties. In addition to the normative calibration scope such as external, internal, depth and step measurements, the light gap tests and ease of movement tests are also carried out fully automatically with the calibration robot, thus relieving the manual calibration process.

For the calibration of thread rings and thread mandrels, several thread scanners are used in order to be able to make statements on the pitch and flank angle in addition to the usual pitch diameter. For the area of dial test euqipments, several fully automatic dial test euqipment test stations are in use, which determine process-reliable and reproducible measured values via a camera system without operator influence. Furthermore, we are optimally equipped for the calibration and measurement of your individual workpieces, test euqipments, assemblies and much more.

Furthermore, our long-standing exclusive partnership with the manufacturer Keyence distinguishes us. This gives you the opportunity to carry out accredited calibrations of optical measuring instruments directly at your premises with minimum downtime.

Your advantage: Our competence

- Extensive calibration portfolio

- Fully automated measuring robot

Our innovations:

- 2D/3D coordinate measuring technology and CT scanning

- KEYENCE Exclusive Partnership

Indicating measuring equipment

In the dimensional laboratory of Testo Industrial Services, almost all types of indicating length measuring equipment are calibrated at constant temperatures of 20 °C ± 1K.

For example, the laboratory has several fully automatic dial test equipment test stations. Analog and digital dial indicators up to 100 mm are calibrated in the shortest possible processing time using a process-safe camera reading system. In addition, we determine the linearity of the displacement sensors at our displacement sensor measuring station according to the respective manufacturer's specifications. Here, with an increasing number of electronic displacement sensors, the individual test positions are approached fully automatically with a linear motor axis at high speed. In addition, the calibration of tape measures and scales up to 100m is possible with our tape measure test stand.

At our measuring stations for indicating measuring equipment, we are specialized in the following test equipment:

- Caliper

- Outside micrometers

- Mechanical and digital dial test equipments

- Fine pointer

- Tape measures/rulers/flat rulers

- Angle/protractor

Measuring robot for calipers

The vernier caliper is one of the oldest testing devices in industry. Due to the high number of calibrations per day, many processes are optimized and automated in order to relieve the time-consuming manual, very operator-dependent calibration process.

Our laboratory has a fully automated measuring robot, which calibrates calipers for you within a very short time, with very low measurement uncertainties. In addition to the normative calibration scope such as external, internal, depth and step measurements, the light gap tests and ease of movement tests are also carried out fully automatically with the calibration robot up to a measuring range of 300 mm.

At our measuring robot for calipers we are specialized in the following test equipment:

- Vernier caliper

- Caliper with numerical display

Test gauges and material measures

Several horizontal linear encoders with a maximum length of up to 1000 mm for external measurements or up to 800 mm for internal measurements and thread scanners are used in the dimensional laboratory of Testo Industrial Services as reference measuring equipment in the calibration of length and dimensional standards.

Our qualified personnel perform the calibration of cylindrical and tapered external, internal and thread measurements. In addition to the simple pitch diameter (calibration option 1), we also determine other thread parameters such as pitch, outside, core diameter and profile angle (calibration options 2-5).

At our length measuring devices we are specialized in the following measuring devices:

- cylindrical and tapered plug gauges

- cylindrical and tapered ring gauges

- cylindrical and tapered thread plug gauges

- cylindrical and tapered thread ring gauges

- Test pins

- Setting standards

- Feeler gauges

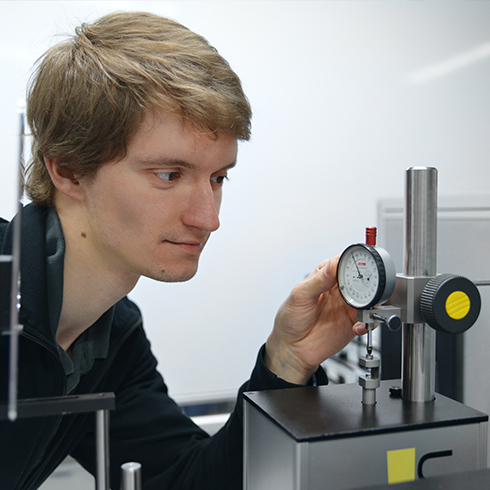

Gauge block test station

Gauge blocks are mostly used for checking calipers, outside micrometers or as high-precision measuring standards. To ensure that the measuring equipment provides representative and reliable measured values, regular calibration of these gauge blocks is recommended. As a recognized calibration laboratory, Testo Industrial Services has the expertise and the corresponding gauge block test stations.

We calibrate for you in compliance with standards according to VDI/VDE/DGQ 2618 sheet 3.1 in a measuring range of 0.5 mm to 150 mm.

At our gauge block test station we are accredited for the following measuring instruments:

- Steel gauge blocks

- Ceramic gauge blocks

- Tungsten caride (hard metal) gauge blocks

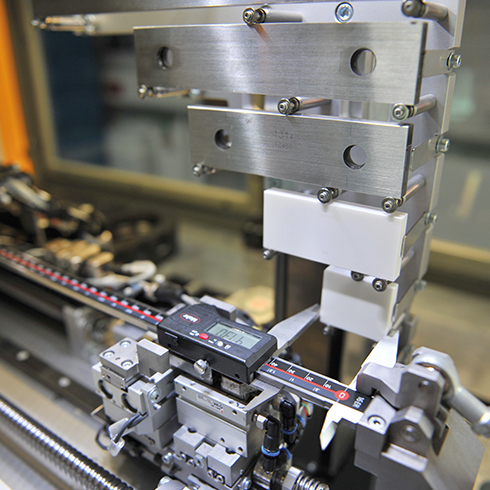

Linear displacement sensors

We use our linear motor axis to determine the linearity of a wide range of displacement sensors according to the manufacturer's specifications with an accredited measuring range of 1000 mm. As the number of electronic displacement sensors increases, the individual test positions are approached fully automatically at high speed.

With our linear motor axis, we specialize in the following measuring devices:

- potentiometric draw-wire displacement sensors

- rod potentiometers

- laser triangulation sensors

Coordinate metrology and 3D scanning processes

Testo Industrial Services GmbH has a large number of high-precision coordinate measuring machines which are suitable for testing standard geometries and special geometries. These include special gauges, gear wheels, gearbox housings, turbine blades, cylindrical screws and much more. In addition to the calibration of your dimensional, form and positional tolerances according to the geometric product specifications (GPS), we offer the inspection equipment monitoring of your test equipments, master parts (setting masters), inspection fixtures and other traceable inspection equipment. This calibration scope is rounded off by the option of measuring your complete clamping fixtures and assemblies to the ideal dimension and adjusting them if necessary.

At our coordinate measuring machines we are specialized in the following measuring devices:

- Gradient test equipments

- Gear test equipments

- Special thread test equipments (internal and external)

- Calibration standards

Measuring microscopes

Test equipment is often flat, sensitive or small and can only be measured tactilely by probing to a limited extent. Optical measuring microscopes, on the other hand, often reveal things that can only be guessed at by the human eye thanks to their magnification capabilities.

With our long-standing and exclusive cooperation with the measuring instrument manufacturer Keyence, Testo Industrial Services ensures the accuracy of your optical measuring instruments and, in addition to the calibration and adjustment programs agreed with the manufacturer, also carries out accredited calibration directly on your premises.

At our measuring microscopes we are specialized in the following measuring instruments:

- Radius gauges

- Tapping gauges

- Optical measurements according to customer drawings

- Accredited calibrations for optical measuring microscopes and profile projectors

Success stories

We support you in your projects and are committed to your goals. Here you will find an excerpt from the references of our successful projects:

Know-how

Our know-how summarised for you: In our Knowledge Centre you will find helpful know-how from our experts on dimensional calibration, or dive into interesting technical articles about calibration.

To read

Discover our comprehensive service portfolio. As a full-service provider in the field of measurement technology, we are your optimal calibration service provider.