2D and 3D coordinate measuring technology

Do you need test reports or calibration certificates for your special test equipments? With our many years of know-how and extensive range of test machinery, we would like to be your first choice for calibration and measurement of standard and special geometries.

Coordinate metrology is the most accurate method for recording and measuring products and objects in their entirety. Within the test procedures, the most diverse parameters of components, such as distances, diameters, angles, shape and position can be checked. The measurements are not only possible for standard geometries, but also for any free-form surfaces.

With the expansion of the dimensional laboratory to include coordinate measuring technology and 3D scanning processes, we offer a comprehensive service portfolio.

Your advantage: Our competence

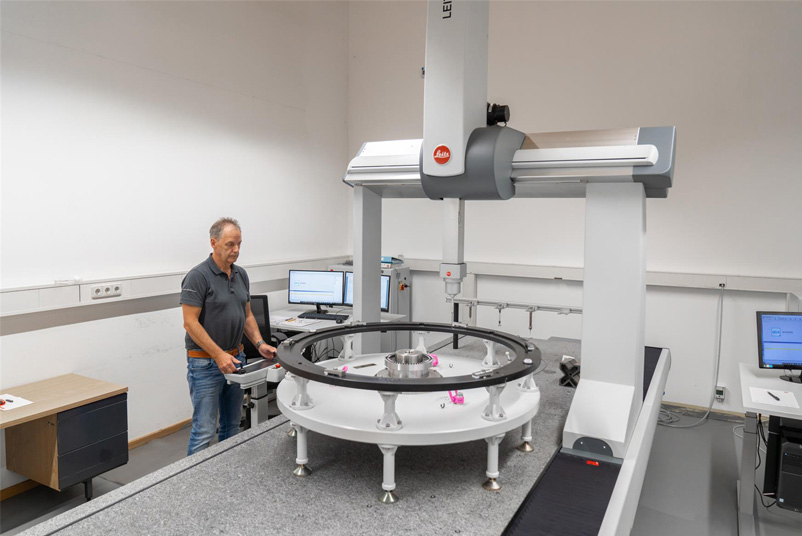

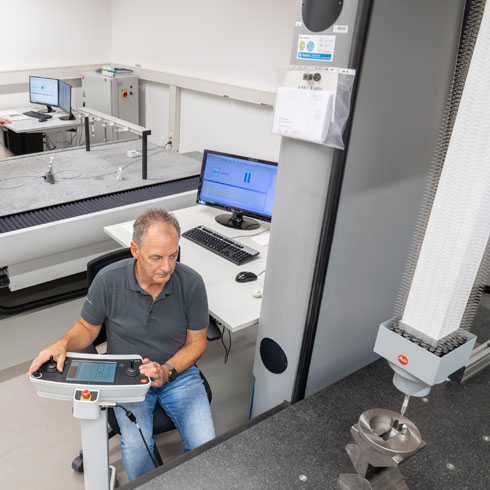

- Measurement of individual components on four high-precision coordinate measuring machines (CMM)

- CMM measurement uncertainty of 1.3 µm + L/500

- Test reports for your workpieces and components

- DAkkS-accredited calibration in coordinate measuring technology of prismatic, conical and spherical workpieces up to 3 metres

- Optical measurements and testing of form deviations with fringe light projection and industrial computer tomography

We will be happy to support you and advise you without obligation. Do you already have a specific request?

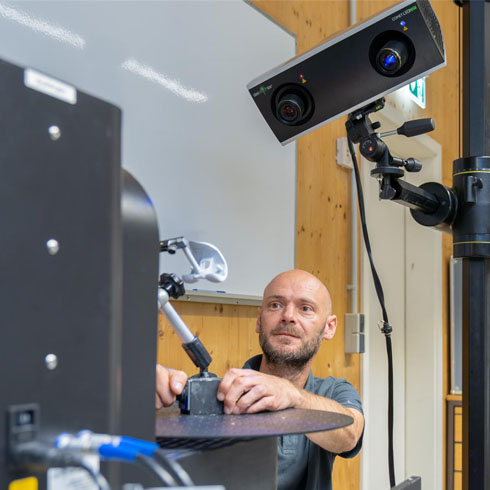

Insight into our laboratory

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.ISO and DAkkS accredited calibrations for your test equipments and master parts

Test equipments and master parts must be calibrated regularly for proper use. This is the guarantee for reliable and standard-compliant measurement results in all manufacturing companies. With our high precision CMMs and a sound calibration process, we are ideally equipped to measure your test equipments and master parts.

Here we are specialised for:

- Gradient test equipments

- Gear test equipments

- Special thread test equipments (internal and external)

- Setting rings and setting mandrels with roundness and form deviation

- Calibration standards

- And many more traceable test equipment

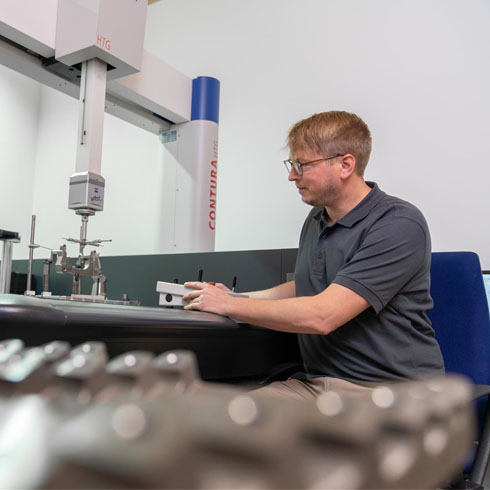

Test reports for your workpieces and components - with tactile measurement technology

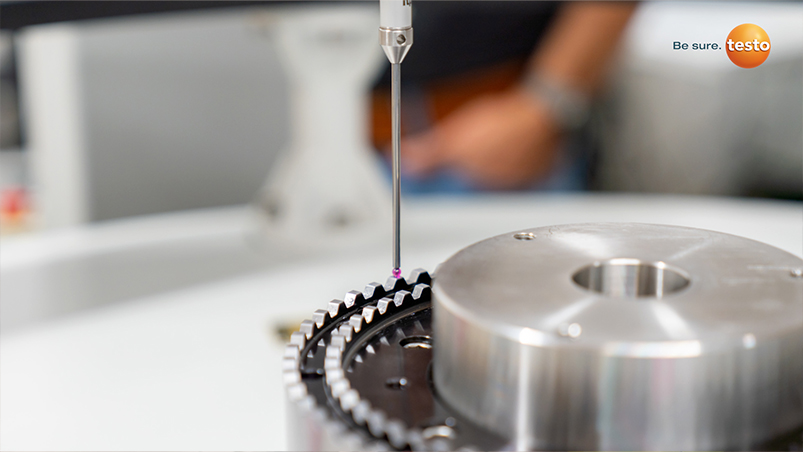

In addition to our calibrations we offer test reports for your workpieces and components. Here we also test and measure on our high-precision CMMs for a safe and reliable result. In addition to the creation of customer specific initial sample test reports of e.g. plastic and injection moulded parts, we also test special geometries and also carry out gear tests with all types of gearing (feature oriented tests).

With the help of our wide range of measuring equipment and a swivelling measuring head, we are able to test even the smallest modules of internal gears.

Here we are specialized for:

- Gears (internal gears, external gears, involute gears and many more)

- Worm wheels

- Housing

- Covers

- And many more, most different components

Test reports for your workpieces and components - with 3D scanning process

In addition to tactile measuring methods, we are also able to carry out optical measurements using 3D scanning methods. Scanning of the geometric shape of the object to be measured is contactless and based on the physical principles of reflection and absorption. This enables us to digitise unknown free-form surfaces and perform reverse engineering.

The high stability of the mechanical structure and the optics specially developed for the COMET L3D sensor guarantee the highest measurement accuracies. The high-precision fringe light projection as well as the integrated rotary and swivel table lead to an optimal detection of all surfaces, corners and edges of your component.

Complex geometries of your components can be analysed non-destructively and evaluated in digital form by industrial computer tomography (ICT). Especially for very small components from medical technology, this possibility is limitless.

Test reports for your complete assemblies and clamping devices including adjustment

The testing of your complete assemblies and clamping devices is also possible on our coordinate measuring machines. With our extensive measuring volume of X=3000 mm x Y=1200 mm x Z=900 mm, even large assemblies can be measured without any problems. In addition, we have the know-how to adjust them if necessary.

Know-how

Here our know-how summarised for you: Learn more in our interesting technical article on the topic of coordinate metrology. In our Knowledge Centre you will also find helpful know-how from our experts on dimensional calibration.

Our services for you

Dimensional

Learn more about our scope of services in our dimensional laboratory.

Mechanics

Testo Industrial Services is also distinguished by its extensive mechanical laboratory.

Calibration

Over 60 years of experience in measurement technology make Testo Industrial Services the ideal calibration service provider